Our lab and special energized

metal fittings for Crystal Magic Film.

Special energized metal fittings

for Crystal Magic Film

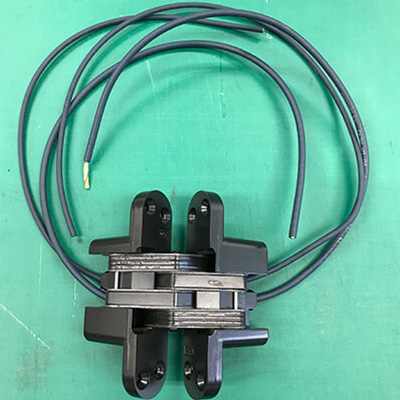

When installing to a hinged door or sliding door instead of using a crystal magic film or crystal magic glass to kill a window (FIX), it is necessary to use a special energized metal fitting. Below, we will introduce various types of energized metal fittings.

When applying crystal magic film to hinged door glass such as stile doors, install the electrodes on the hanging side and pass the wires through the dedicated energized metal fittings.

When constructing a wooden stile door glass, etc., use a hidden hinge-shaped energized metal fitting, and when the door is closed, the hinge is hidden and the finish is neat.

When installing wooden frame door glass, the use of a concealed type of electrical accessory will make the hinges invisible when the doors are closed, creating a neat appearance.

-

When OFF

When OFF -

When ON

When ON -

Special electrical accessory to be used

Special electrical accessory to be used

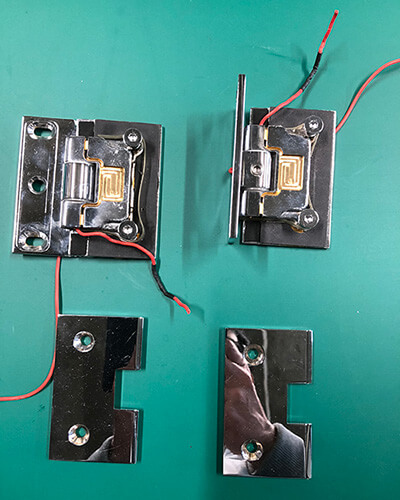

When applying Crystal Magic Film to tempered glass around a washroom, use a specially processed hinge. (Cannot be used in places where it is directly exposed to water, i.e. bathroom)

-

When OFF

When OFF -

When ON

When ON -

Special electrical accessory to be used

Special electrical accessory to be used

For sliding glass doors, special energized metal fittings are used. The operating range of the left and right doors is up to 1000mm.

It is necessary to take 100mm or more to hide the hanging source.

Crystal Magic Lab

We design energized metal fittings for crystal magic film. We cut the film, manufacture and process electrodes, in a dedicated laboratory. We strive each day to make the highest quality and durable products.

The magic film lab cuts the crystal magic film, manufactures the electrodes, conducts the energization test, and designs the energized metal fittings for the LCD dimming film.

The lab is equipped with a machine that can cut right angles in all directions with an accuracy of millimetres (± 0.5 mm) up to W2100 x H3600. The manufactured magic film is then carefully packed and shipped as a product after undergoing an ON / OFF switching test 100 times in a row and an energization test for 3 hours in a row.

In addition, since the 1200-width and 1500-width 30m raw rolls are always in stock at the laboratory, the material loss rate can be kept to a minimum and efficient material can be supplied, and all requirements can be addressed quickly.

Packing of Crystal Magic Film

Due to its characteristics, liquid crystal film cannot be packed like ordinary film. It is carefully packed and shipped in a paper tube with a diameter of 260 m / m.

Since the edges of the LCD film are easily damaged, we pack the paper tube in a floating state and make sure that it reaches the site in a sideways position even when it is delivered. Especially when applying to twin glass, the quality of the film edge has a great influence on the finish, so the packing condition is very important.

In addition, all packaging materials are recyclable and are environmentally friendly.